AUTOMATIC SEAMER

Type if seaming: stationary can seaming system.

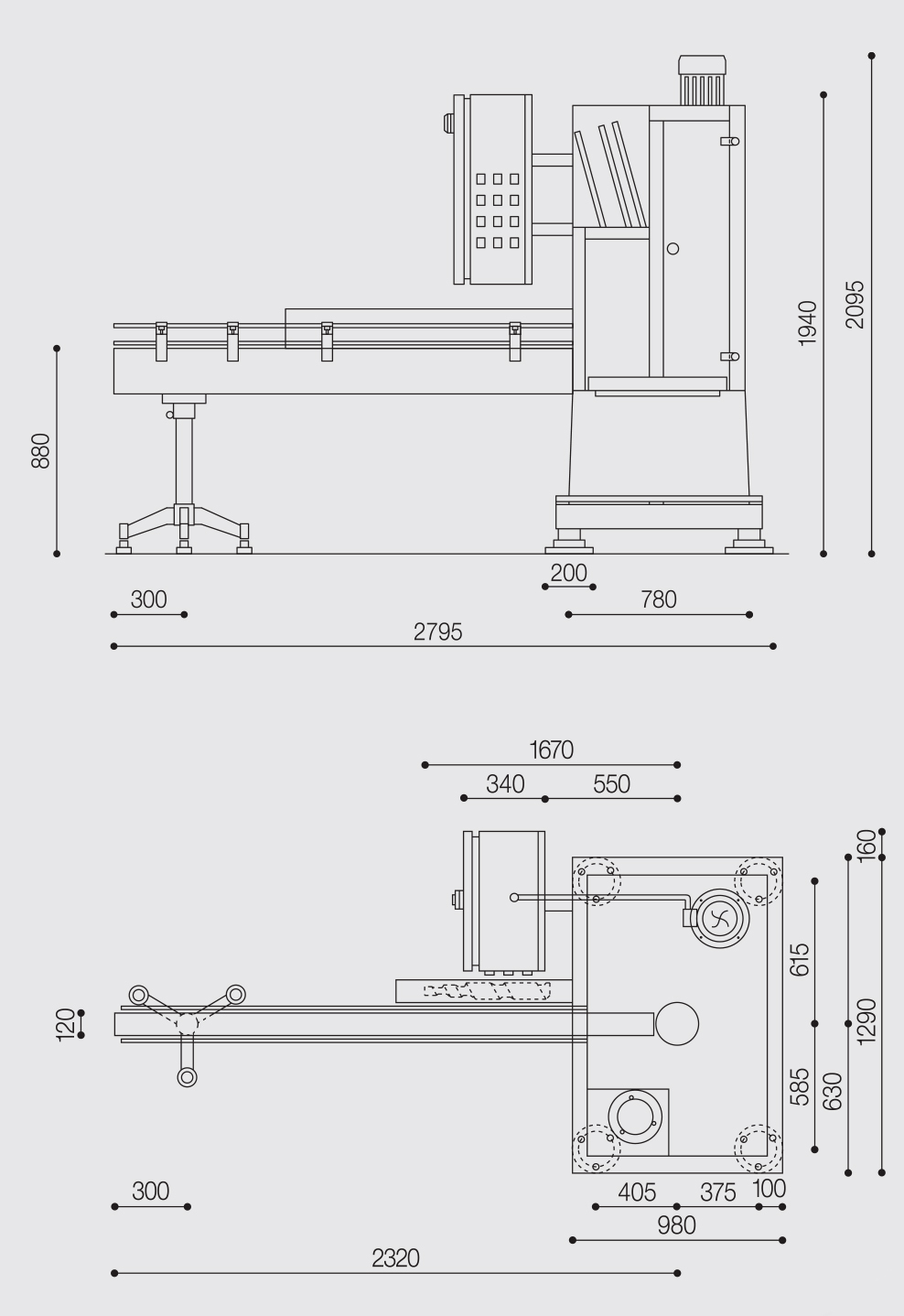

The solid and reliable automatic seamer mod. F70 has been built and improved from years of technical experience. The machine handles cans with diameters of 65 to 230mm and heights of 24 to 220 mm.

The seamer consists of two cast monoblocks and one inlet conveyor with a worm to synchronize the cans.

The base is made from an AISI 316 casting stainless steel and its weight gives the machine greater stability, while the high quality material protects against corrosive and aggressive products, such as sugar, salt, vinegar etc.

The upper head is made from nickel surface treated cast iron.

The height of the head can be adjusted manually with a hand wheel, allowing for quick and frequent changeovers, although an electrical option is also available.

The machine is powered by a 4 kW motor, plus an inverter to regulate the production speed from 15 to 60 cpm.

The control panel is provided with a portable controller (JOG) for impulse running, useful during maintenance, cleaning and changeovers.